COPYRIGHT © Shandong Pengcheng Ceramic New Material Technology Co., Ltd. 鲁ICP备15040828号 Powered by www.300.cn

Boron nitride ceramic

Boron nitride ceramic

BORON NITRIDE CERAMIC PRODUCTS DESCRIPTION

PENSC hot-pressed hexagonal Boron Nitride Ceramic Products, exhibits a unique combination of chemical,electrical,mechanical and thermal properties, making it suitable for a wide range of highperformance industrial applications. PENSC can supply the high purity or include difference binder boron nitride ceramics, complete solution based on kinds of industry customers demand.

FEATURES /BENEFITS

● Excellent thermostable performance (Temperature ≥ 2000℃ in Vacuum and inert atmosphere)

● High thermal conductivity

● Low thermal expansion, excellent thermal shock resistance.

● Outstanding electrical insulation properties at high temperatures.

● High wet resistance to molten metals,slags and glass.

● Extreme corrosion and wear resistance.

● Easily machinable to desired shapes and size.

KEY APPLICATIONS

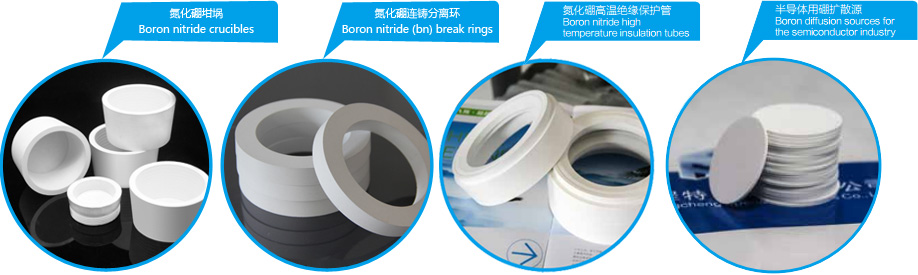

● Insulators for high-temperature furnaces.

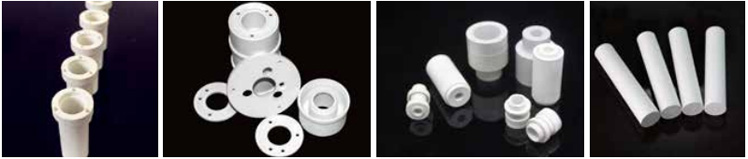

● Amorphous system nozzles and Powder metal atomization nozzle

● High temperature mechanical components such as bearing,valves,spacers.

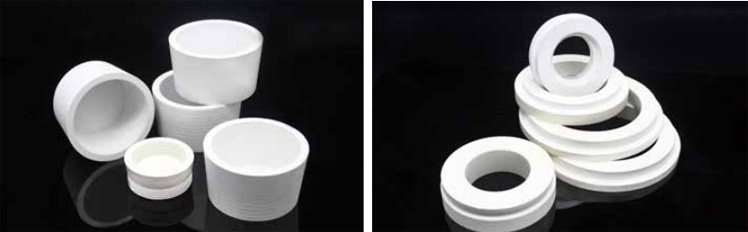

● Crucibles and molds for molten metal processing.

● Separating Ring for Horizontal Concasting.

● Muffles and crucibles for Nitride and Sialon firing.

● P-Tpye diffusion sources for the semiconductor industry.

Boron nitride ceramic product performance technical parameter table

Typical Properties |

Unit |

PBN-A | PBN-B | PBN-C | PBN-D | PBN-E | |||||

| Binder | No |

Yes | Yes | Yes | Yes | ||||||

| Typical Applications |

Extreme Corrosion Resistance, Thermal Conductivity, Purity. Applicable to ultra high temperature insulation and high purity crucible and others. | General-purpose, High density, Ease of processing, The best choice in inert and dry environment. | Outstanding Moisture Resistance, Refractory, Dielectric Strength. Ideal for light metals (aluminum, magnesium, zinc) processing applications. Especially suited for electrical insulation in temperature 1000℃ | Extreme Thermal Shock, Moisture Resistance, Dielectric Strength. For extreme harsh dielectric properties of applications. | Extreme Wear Resistance, Corrosion & Thermal Shock. | ||||||

| Color | White | White | White | White | 灰色 White |

||||||

| Density | g/cm3 | > 2 | > 2 | > 2 | > 2 | > 2.3 | |||||

| Directionality | Level | Vertical | Level | Vertical | Level | Vertical | Level | Vertical | Level | Vertical | |

| Mechanical Properties | |||||||||||

| Flexural Strength | Mpa | 22 | 21 | 94 | 65 | 59 | 45 | 62 | 34 | 144 | 107 |

| Youngs Modulus | Gpa | 17 | 71 | 47 | 74 | 40 | 60 | 71 | 71 | ||

| Hardness-Knoop | Kg/mm2 | 4 | 4 | 20 | 20 | 16 | 16 | 100 | 100 | ||

| Thermal Properties | |||||||||||

| Thermal Properties at 25℃ |

W/mK | 78 | 130 | 30 | 34 | 27 | 29 | 11 | 29 | 24 | 34 |

| Coeff.of Thermal Expansion(10-6) |

|||||||||||

| 25-400℃ | -2.3 | -0.7 | 3.0 | 3.0 | 0.6 | 0.4 | 3.0 | 0.4 | 4.1 | 3.4 | |

| 400-800℃ | -2.5 | 1.1 | 2.0 | 1.4 | 1.1 | 0.8 | 2.5 | 0.1 | 5.4 | 4.3 | |

| 800-1200℃ | 1.6 | 0.4 | 1.9 | 1.8 | 1.5 | 0.9 | 3.0 | 0.1 | 7.2 | 5.2 | |

| 1200-1600℃ | 0.9 | 0.3 | 5.0 | 4.8 | 2.8 | 2.7 | 4.6 | 3.4 | |||

| Specific Heat at 25℃ | J/gK | 0.81 | 0.81 | 0.86 | 0.86 | 0.81 | 0.81 | 0.76 | 0.76 | 0.64 | 0.64 |

| Max. Tem- Oxidizing/ Inert |

850℃ /1800℃ /2300℃ | 850℃ /1600℃ | 850℃ /1150℃ | 850℃ /1600℃ | 850℃ /1600℃ | ||||||

| Electrical Properties | |||||||||||

| Dielectric Cons | 4.0 | 4.0 | 4.6 |

4.2 |

4.3 | 4.0 | 3.5 | 3.7 | |||

| Dielectric Strength | KV/mm | 79 | 88 | >10 | 66 | >9 | |||||

| RT Resistivity(ohm cm) | Ω cm | >1013 | >1014 | >1013 | >1014 | >1013 | >1013 | >1013 | >1013 | >1013 | >1015 |

MACHINING CONSIDERATIONS

PENSC Solid Boron Nitride Grades A,B,C,D and E are truly machinable ceramics, according to the need to produce complicated

shape in little tolerance. Boron Nitride Solids Machining Considerations as follows:

● PENSC Solid Boron Nitride Grades A,B,C,D can be machined using standard high-speed tool steel cutting tools. Carbide tipped tooling is recommended for maching Grades E and Composite materail.

● Machining by grinding may be done if preferred. Threads can be machined using standard taps and dies.

● Cutting oils and coolants are not necessary and should not be used.

● Cutting tools should be sharp and clean and cutting tools with negative rake angles should never be used.

● Care should be taken when chucking and clamping so that excessive pressure is not exerted. Climb milling techniques should be used to prevent corner and edge.

● Boron Nitride solids be kept dry at all time , stored in airtight bags, containers or in dry ovens.

PENSC machining center have many sets of CNC lathe,CNC milling machine. We have rich experience in processing and can produce kinds of bn products according customer requirement.